Designing a heavy tilt-rotor aircraft in T-FLEX CAD

Author: Plotnikov Alexey, Top Systems Ltd. Head of Marketing

Designing a heavy tilt-rotor aircraft in the T-FLEX CAD – What can you learn in the Top Systems?

The Top Systems company utilizes the idea of teaching designers using industrial examples instead of primitives for quite a long time. Design methods evolve as the T-FLEX CAD become more and more powerful and complex system. Here is the example, which conveniently demonstrates system’s capabilities.

The heavy tilt-rotor aircraft project was created by one of our engineers using information from open sources and his own experience in aircraft design study. Studying the subject took about two months plus about six months for the design itself. Quite impressive!

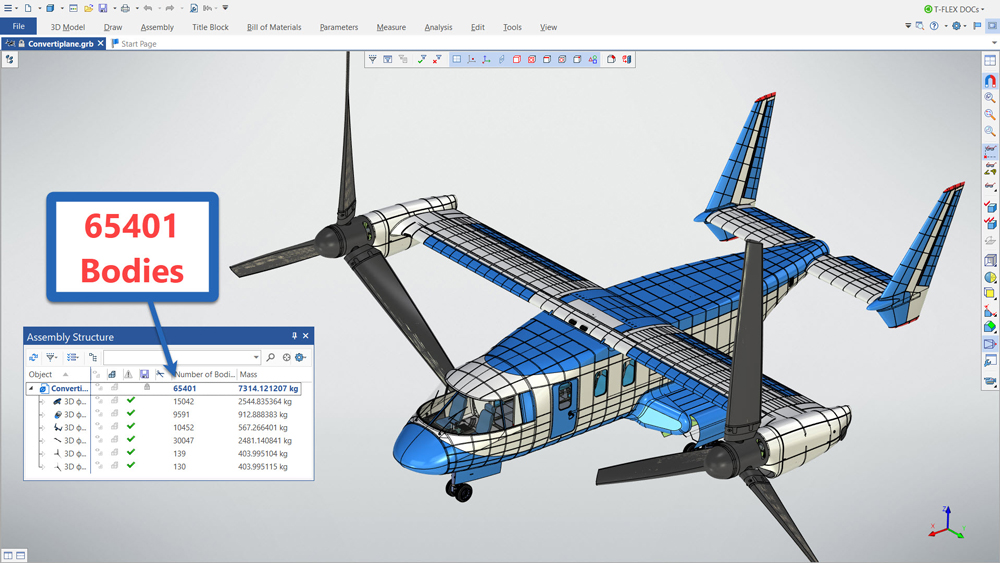

The tilt-rotor aircraft created in the T-FLEX CAD 16 is one of the most complex and detailed assemblies. It contains over 6000 bodies, complex surfaces, detailed design of each unit. The whole assembly “weighs” a bit over 3.8 GB.

The power plant (aircraft is equipped with two of them) – over 5000 bodies in a single engine.

The assembly contains thoroughly designed spars, hydraulics, wiring (not tens of kilometres like on a real aircraft, but still), rivets and other fasteners. Mates are created in the assembly – rotor blades can be rotated, the assembly control dialog is added. So the parametrization plays the important role in creating and managing such extremely complex model:

Moreover, the model contains “fair” assembly structure and product composition. Some part of the work was done in the T-FLEX DOCs integration mode and the final model is fully loaded into DOCs.

The aircraft fuselage level of detail is clearly visible.

By the way, we show the aircraft cockpit in virtual reality directly in the T-FLEX CAD without any additional preparations and simplifications. This is achieved by using the T-FLEX VR application, which allows not only viewing and navigating the model, but also take measurements, evaluate the ergonomics, manage visual parameters of assembly fragments and edit certain components.

Aircraft cockpit interior.

The “fair” solid 3D model is rotated in the 3D scene without applying any large assembly optimisation mechanics, simplifications and other tricks to speed up the process. Of course, such tools are available in the system, but the purpose of this model is to demonstrate the full power of the T-FLEX CAD.

Long story short, the rotation is performed at high speed which can be seen in the video below recorded in real-time. Notice how smoothly such huge assembly rotates! (The 3D mouse was used, when recording the video):

Here’s couple of numbers describing the rotation of the model in the 3D scene: framerate – 60 FPS, antialiasing – 8x.

Summary

The project turned out to be complex and comprehensive. It allowed us to increase our experience and we are ready to share this experience. Top Systems provides professional training courses on using T-FLEX PLM complex products at our corporate training centre. We also apply best practices to implementing our products at client’s site. If you’re interested, we are always online and ready to answer your questions!