3D Weld Geometry Types: Butt |

|

A butt weld connects the entire surface of the two sets of faces being welded. The number of faces in the sets doesn't have to match. The selected faces must belong to one or two bodies. To ensure the correct orientation of the butt weld, you need to additionally specify the top and bottom faces for each set of faces being welded. Those define the required correspondence to construct the weld body. Specify the top and bottom faces by picking ones among those having common edges with the faces being welded.

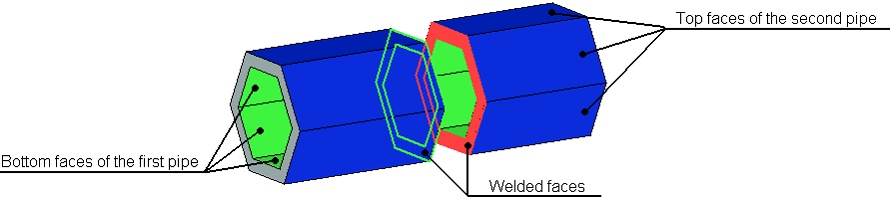

For example, when creating a butt weld between two pipes of the round section shape, you select the outer cylindrical faces of both bodies as the top faces. The bottom faces in this case will be the inner cylindrical faces. Or, you can do the opposite, as far as the outer face of one body matches with the outer face of the other body, and so do the inner faces.

|

|

When creating a butt weld between two pipes with a noncircular section shape, select all outer faces of both pipes as the top faces, and all inner faces - as the bottom faces. At the same time, if several top faces are specified on each of the bodies, then the order of selecting faces on one body must match the order of selecting faces on the other body. The same is true in the case of selecting several bottom faces on each of the bodies.

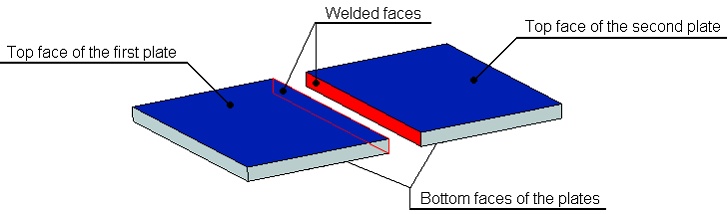

When creating a butt weld between two plates, you select the top and bottom faces as the ones, along which the weld will go. Please note that the top face on one plate must be on the same side as the top face on the other plate.

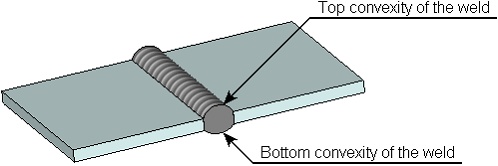

In the case of the butt weld, you can specify the contour type (flush, convex, concave) on either side of the parts being welded (that is, on the sides of the top and bottom faces). The weld contour from each sides of weld is specified as the maximum deviation of the curved face line of the weld from the straight line.