Example of Converting Body to Sheet Metal |

|

The example of using the Convert Body to Sheet Metal operation is demonstrated in this section. Besides, a case when it is necessary to change bending procedure is considered.

Let's say, a solid body, which needs to be converted into sheet metal, is already created in the current document.

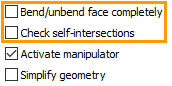

Before we start the conversion, we should edit ![]() Sheet Metal Default Parameters. Remove the flags from Bend/Unbend face completely and Check self-interactions options. Now in case of self-intersections of metal sheets the system can show the body obtained this way at the screen. If you leave the flags, the system will not be able to show the self-intersecting body and will display an error.

Sheet Metal Default Parameters. Remove the flags from Bend/Unbend face completely and Check self-interactions options. Now in case of self-intersections of metal sheets the system can show the body obtained this way at the screen. If you leave the flags, the system will not be able to show the self-intersecting body and will display an error.

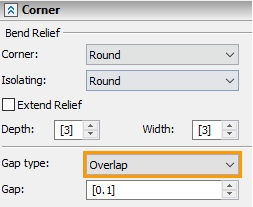

Now call the Convert Body to Sheet Metal command and select elements in 3D scene in the order shown in the picture below. First, a stationary face is selected. Then three edges of the body are selected in turn. Before executing the operation it was specified in the Corner tab in the parameters window that sheet edges must overlap.

|

|

|

Selecting stationary face |

Selecting first edge |

Selecting second edge |

|

|

|

Selecting third edge |

Result |

Result |

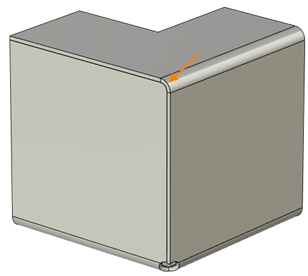

After the operation is executed, we obtain a solid body with two sheets with non-deformed corners crossing a rounded face. This is because the body folding sequence was given incorrectly.

This is exactly one of the cases when it is helpful to change edges folding sequence. It helps to avoid self-intersection of the bodies, at the same time you don’t have to re-set the edges manually.

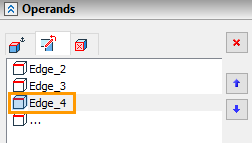

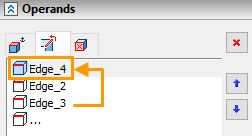

Operands tab shows edges selection sequence for the operation. Use arrows ![]() and

and ![]() to change folding sequence.

to change folding sequence.

Move the last of the selected edges two lines higher, selecting the required edge and pressing up arrow and repeat operation creation. Now the sheets adjoin each other smoothly and don’t intersect.