Free Instance Orientation in Parametric Sweep |

|

Free instance orientation approach

To create a parametric sweep, simply select a 3D profile, specify the number of instances and assign an independent variable to the parameter Copy Number. Using the variable that follows the instances enumeration, one can create certain dependencies for the driving parameters, as well as for 2D or 3D constructions, which, in turn, define the shape and position of the 3D profile.

One can select the 3D Profile by using the respective option in the automenu:

|

<R> |

Select Contour |

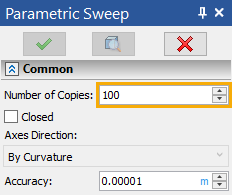

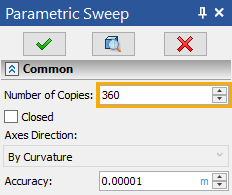

The number of copies of the profile can be assigned in the Common tab in the operation parameters window.

Besides the Number of Copies parameter, this tab also contains an accessible option Closed. With this option on, the body being created from the set of the sections (the set of the instances of the original profile), will be smoothly closed, as if the first section was selected twice.

After setting the number of copies, you can go to the Parameters tab.

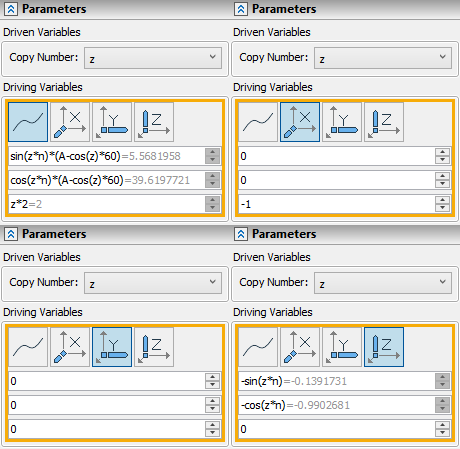

This tab has two types of parameters, grouped under the names Driving Variables and Driven Variables.

When creating the operation following this approach, the only driven parameter is the copy number, while the driving are the parameters responsible for positioning the current profile instance in space. For convenience, four groups of driving parameters are defined:

- Position on Path

- X axis direction

- Y axis direction

- Z axis direction

![]()

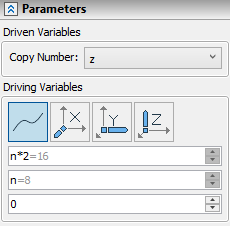

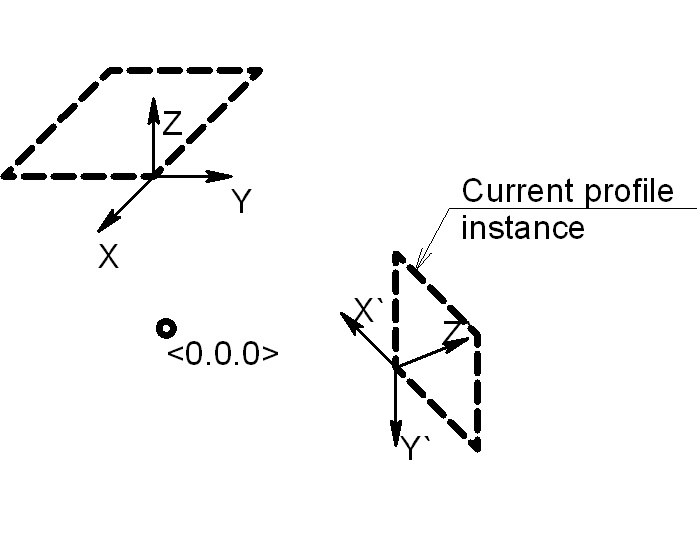

For each group of control parameters, input of the X,Y,Z coordinates of the point determining the position of the origin of the coordinate system of the current copy is available.

The rest of parameters define the three vectors used for orienting the coordinate system of the current instance.

You can explicitly describe the position of the current instance coordinate system as a function of the copy number. To do this, define the required dependency in the group of driving parameters (by entering the names of existing variables that directly or indirectly depend on the copy number).

Each vector defining the direction of a coordinate system axis of an instance is defined by two points. The first point coordinates are <0,0,0>. The coordinates of second points of the direction vectors for the current instance's coordinate system axes are defined by the parameters X, Y, Z from the respective group of driving parameters.

In the case when the vectors defined by the user are not orthogonal or do not make a right-oriented coordinate system, the system refines the definition automatically. Axes definition is done in the order: X, Y, Z. The X-axis direction is left unchanged, the Y-axis is rotated to yield the 90° angle in the XY plane, and then the Z-axis is defined.

In the case when only two vectors are defined (for example, the X and Z-axes), then the order of defining vectors changes, and the third vector (of the Y-axis) is defined last.

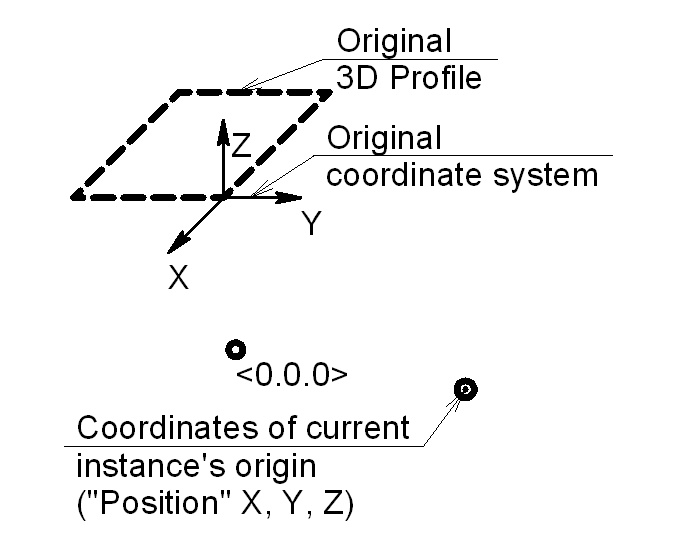

Each profile instance is obtained by carrying a copy of the original profile from the global coordinate system to the computed at the given step coordinate system of the current instance.

Additionally, one can select a local coordinate system by using the automenu option:

|

<6> |

Select source LCS |

In this case, the selected coordinate system will be used instead of the global one when carrying over the copies of the original profile.

When creating a parametric sweep following the described approach, the system computes the position and orientation of the current instance of the profile in the following order:

1. The variable reading the copy number is incremented.

2. The absolute coordinates are computed of the origin of the current instance coordinate system. The computation is based on the expressions entered in the driving parameters fields.

3. The coordinates of the vectors are computed, defining the directions of the current instance's coordinate system axes.

4. The coordinate system of the current instance is created in the computed point of the origin, oriented according to the computed direction vectors.

5. If the geometry of the 3D profile depends in some way on the variable that reads the current copy number, then the profile will be recalculated with the current variable value.

6. The original profile's copy is carried over from the original coordinate system to the obtained coordinate system of the current instance. If the original coordinate system was not specifically selected, then the global coordinate system is used as the original when carrying over a copy of the profile.

After calculating all instances of the original profile, the result is united in one solid or surface body using spline surfaces.

Example 1

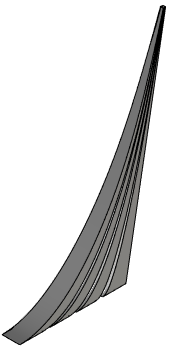

As a first example, let's create a rather simple model.

Let's skip the details of creating the auxiliary 2D and 3D construction elements. Instead, let's briefly review the technique itself. This model can be created by sweeping a 3D profile in the space that is indirectly tied to several guides. Let's use four guides in the 2D view, two of which will define the elevation view, and the other two - the left side view. Three guides are straight lines, and one is a spline.

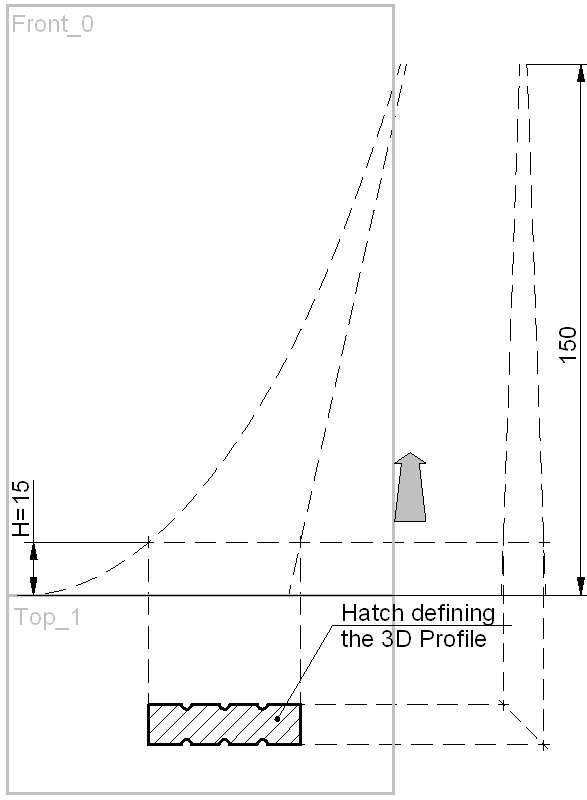

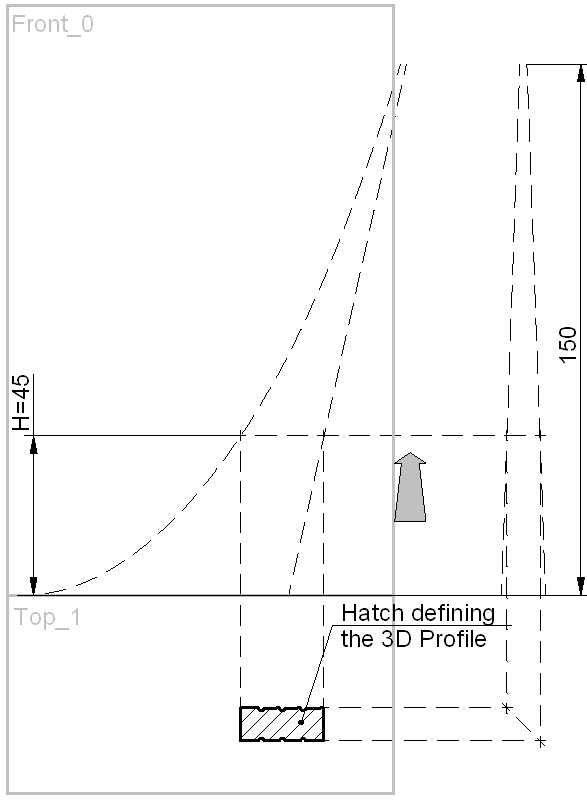

The horizontal construction line is drawn. The position of this line is defined by the expression

"H-1". Therefore, it depends on the variable "H".

Since the Number of Copy parameter values sequence begins from one, sometimes a correction (–1) is required in the expressions where the variable Number of Copy is entered. In this example, the first instance of the profile should be located at the base, that this at the coordinate Y=0.

Four 2D nodes are constructed at the intersections of the horizontal line and the guides. These nodes can drive the length and width of the profile if attached to vertical lines. A 3D node is created based on one of the 2D nodes in order to fix the profile plane. The grooves on the sides of the profile are constructed in such a way to always divide its side in four equal parts. The grooves radius linearly depends on the length of the profile.

We will need two workplanes – the elevation view and the plan view. The first one is needed for constructing the 3D node, the second - for the profile. The coordinate system origin is located at the model base level (see the diagrams). A straight line is constructed from the origin at the angle of 45° to the horizontal. This line is necessary for establishing the projective relation between the guides on the left side view and the profile hatch on the plan view.

All constructions are interlocked so that varying the variable "H" causes the following chain of modifications: the horizontal line changes its position, that affects the position of the 2D nodes referencing the line. The next link in the chain is modification of the profile hatch geometry and repositioning of the 3D node, to which the 3D profile plane is snapped. Consequently, the 3D profile itself will move in the space.

Among the operation parameters, the variable "H" should be assigned the copy number. Specify the number of copies in the Common tab, corresponding to the type of the model, amended as (150+1=151).

It is not necessary to describe the rule for adjusting the instance's coordinate system, since the original profile adjusts its position due to a direct dependency on the copy number. As a result, each instance's coordinate system coincides with the global coordinate system, and, therefore, the current copy coincides with the original profile in the position and geometrical parameters. What matters is how the original profile moves with variations of the variable "H", that is, with respect to the copy number.

The described approach is convenient for using two-dimensional drawing data for constructing a complex model.

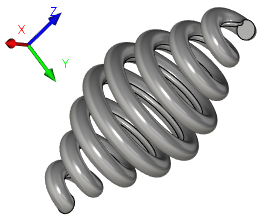

Example 2

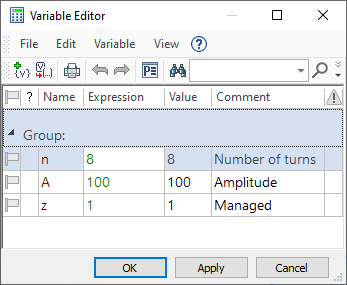

The second example demonstrates the approach to the model creation, when the exact rule is defined for the profile movement. The original data for creating this operation are: a 3D profile; a local coordinate system constructed in the center point of the profile and oriented with respect to the profile as shown in the diagram (the Z-axis lies in the profile plane and is directed towards the groove); several independent variables.

The expressions should be entered in the operation parameters fields, as shown in the following diagrams:

The expressions define the helical trajectory with changing radius. The radius is varied by the cosine function.

The number of copies (profile instances) is equal to 360 due to the following reason: the 360-degree period is used in the expressions of trigonometrical functions.

The diagram shows that the Z-axis of the original profile coordinate system should always be directed towards the center of the spiral (with the groove towards the center), the X-axis – in the opposite direction to the Z-axis of the global coordinate system. The expressions describing these rules are entered in the respective fields of the driving parameters. The Y-axis is defined automatically.