Main Concepts of Three-Face Blend |

|

General operation concepts

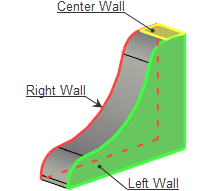

Three sets of faces make the basis of the Three-face blend operation. These are called right, left and center walls. The sets of faces of the left and right walls should have between themselves smooth mates, a set of faces of the middle wall can be mated at a small angle (not more than 5 °). The walls themselves are not required to connect smoothly with each other. All sets of faces can belong either to the same solid body or to one, two or three surface bodies. Three-face blends can’t be created between walls belonging to different solid bodies or mixed surface and solid bodies.

Blending Form

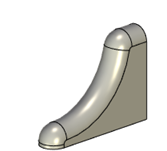

There are two types of blending of three faces: spherical and disk.

For a spherical type, the blending surface is formed by moving an imaginary sphere inscribed between the walls along the entire length of the walls, forming a smooth tangential conjunction at the points of contact with them. The cross-sectional shape of the blending surface is calculated as a spline.

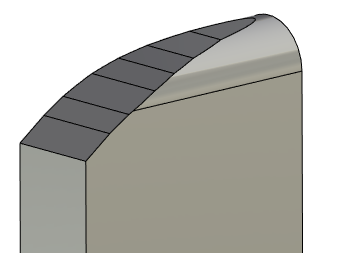

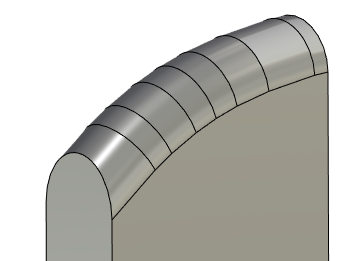

For disc type, the blending surface is formed on the basis of a set of cross-sectional planes and a guide. Planes are built perpendicular to the guide and contain three points of contact where the blending surface touches the walls. The cross-sectional shape of the blending surface in the plane is always calculated as a circular arc that fits in such a way as to ensure a tangency to each wall.

|

|

Original configuration: 1 - Left Wall, 2 - Center Wall, |

Resulting blend |

The guide spine is always represented by a 3D path. The spine may not have sharp corners. If the spine is too short for defining all cross sections, it is extended by straight segments tangent at the ends. If the length of the guide is redundant, then the system tries to choose the part of the 3D path it needs.

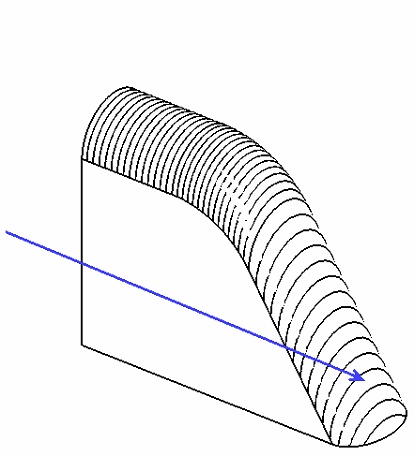

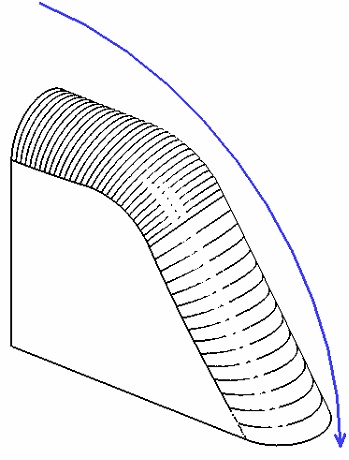

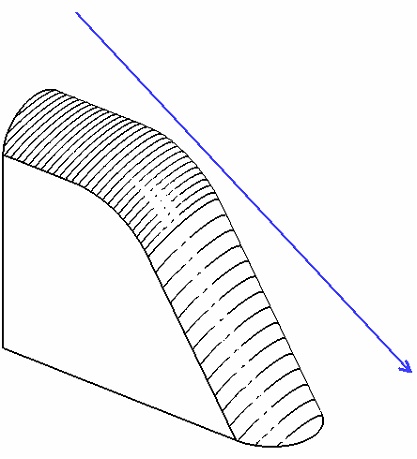

The figures show blend surface geometry dependency on the guide spine

If the left and center walls are adjoining then their common edge (the set of edges) may be used as the guide spine. In this case, selection of the guide spine is optional.

In the case of the use of disk-type construction of the blending surface, when the edge between the left and middle walls has a complex shape, to ensure a successful result between the faces, it is necessary to create a new guide of a simpler shape in comparison with the edge, which approximately repeats its shape. Let's consider two typical examples.

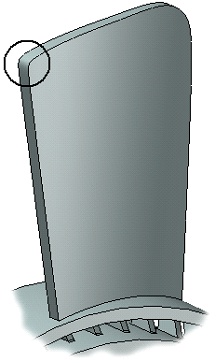

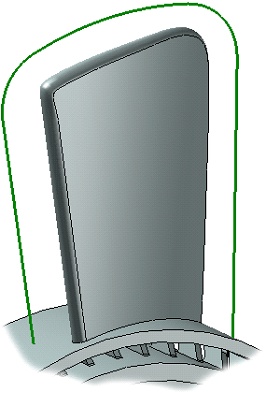

Example 1. It is required to create a blending of the side part of the fan blade with the use of disk construction type. In this case, the system may not use the edge between the left and center walls due to the following reason. The edge has a too small radius in the circled area. The blend cross sections would intersect each other if constructed normal to the edge. An additional spine (a 3D path) helps creating a blend in this case that approximately repeats the shape of the edge yet avoids the mentioned traps.

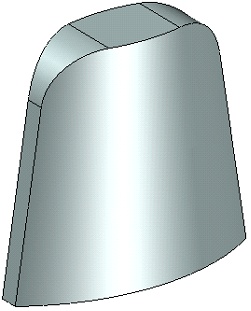

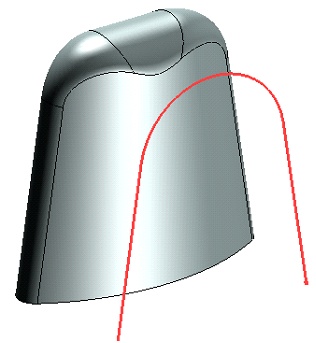

Example 2. In this example, the left and right walls are cone fragments. The part gets wider in the middle. At the first glance, the edge radius is not too small. However, due to the widening part and edge curving in the opposite direction, the system considerably increases the radius of the blend surface that again results in self-intersections. Using a flat spine of the shown shape helps easily create the blend surface.

Adjacent Smoothing

The mode of selecting consecutively paired faces allows the system to automatically select a connected sequence of smoothly adjoined faces of the required wall when specifying one of the faces included in this sequence.

If the adjacent faces of the middle wall are conjugated at an angle, the system allows you to set the angle at which these faces will participate in blending.

Result

When blending three faces of a solid body, the result will always be in the form of a solid body.

When blending three edges of the surface body, or three surface bodies, the system allows to determine the type of the resulting blending:

•No Trim. The blending surface does not join the walls; walls are removed. The result is a surface body.

•Trim Both. The left and right walls are cut off at the points of contact with the blending; the blending surface does not join the walls. The result is individual surface bodies.

•Trim and Sew. The left and right walls are cut off at the points of contact with the blending surface; blending surface joins the walls. The result is one surface body.

•Create Solid. The left and right walls are cut off at the points of contact with the blending surface; blending surface joins the walls and forms a closed space. The result is a solid body.

•Auto. The system independently selects the optimal blending result.

|

|

|

|

|

The Initial Set of Surfaces |

No Trim |

Trim Both |

Trim and Sew |

Create Solid |

The system also provides the ability to create a blending in the form of a separate body, while maintaining the topology of the original bodies.

|

|

|

|

The Initial Set of Surfaces |

Result |

Original solid body |

Result |

Sometimes situations arise when several blending surfaces may exist for a selected set of walls. You can leave them all or specify one specific solution. The system selects the solution closest to the selected 3D point. The 3D point can be a 3D node, a vertex or a middle of an edge.

|

|

|

Source body |

All solutions |

3D node solution |

Trim Blending Surface

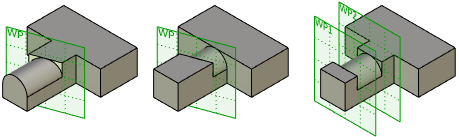

Using flat edges or work planes, you can set a restriction of the blending zone. One bounding plane divides the blending surface into two parts, leaving one of them in the scene. In total, no more than two bounding planes can be specified. Two planes can limit the central part of the blending surface from two sides.

The orientation of the blending boundary depends on the bounding plane and the chosen method of the blending shape. When the Trimming parameter is set, the blending boundary passes along the boundaries of the bounding plane. Otherwise, the blending boundary passes perpendicular to the direction of the blending surface through a point formed in one of the following ways:

•The intersection of the bounding plane and the top blending (for spherical shape blending);

•The intersection of the bounding plane and the given guide (for the disk shape blending).

Trimming by walls (Ends processing)

When creating blending faces, you can choose how to trim the edges of the blending surface. The geometry of the walls themselves when cutting the blending surface is not broken. Total

There are four ways to trim:

•No Trim. In this case, the blending surface is extended beyond the boundaries of all walls.

•By Both Walls. The blending surface is cut along the borders of the left and right walls. In this case, the side edge of the blending surface is formed in such a way as to ensure contact with the side edges of the trimming walls.

•By Short. The blending surface is trimmed along the least distant wall edges.

•By Long. The blending surface is cut along the most distant edges of the walls.

|

|

|

|

|

The Initial Set of Surfaces |

No Trim |

By Both Walls |

By Short |

By Long |

Additionally, the system makes it possible not to take into account the middle wall when creating a blending surface. For example, the option may be useful when creating a body with trimming along the wall in the By Short mode or By Long.

|

|

|

The Initial Set of Surfaces |

By short, taking into account the middle wall |

By short, without taking into account the middle wall |

|

|

|

The Initial Set of Surfaces |

By long, taking into account the middle wall |

By long, without taking into account the middle wall |

The methods of trimming No Trim, By Short, By Long can be used only if the end result is obtained in the form of a surface body.