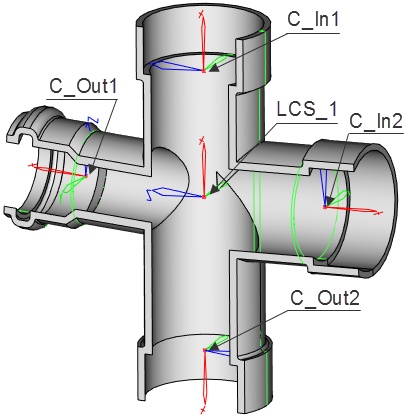

LCS and Connector of Fitting |

|

Table of fitting smart-fragment key LCS.

Object |

Description |

LCS_1 |

The fragment source LCS must be set as LCS by default in the fragment document parameters. |

C_In1, C_Out1, C_In2, C_Out2 |

Connectors names of input/output main and alternative directions |

LCSs listed in the table are responsible for cutting pipe for which fitting is inserted.

LCS_1 responsible for position of fitting on the pipe is the main LCS that must be created for joining fitting with the fragment. The remaining four LCSs are responsible for joining pipes of appropriate diameter and the emergence of the connecting elements (flange and thread) at coupling place of pipe with fitting. These LCSs are considered in macro.

Table of key connector parameters that define smart-fragment insertion logic:

Parameter name |

Usage |

Description |

autoFilePipeEnd |

Pipe ending/beginning if connector is located on pipe end. Can be omitted. |

Template of the parameter value: <library>file_name.grb Parameter functions: - creates cosmetic thread on the pipe - cuts the edge for weld - creates flaring |

autoLength |

The fragments name in the connector direction |

Sum of input and output connector lengths is equal to the length of the direction (main or alternative) |

autoDiameter |

Pipe diameter will be taken from fitting |

If missed the original pipe diameter is used. |

autoThickness |

Pipe thickness will be taken from fitting |

If missed the original pipe thickness is used. |

auto – manages the command operating logic when the smart-fragment with this connector is inserted.

The above parameters allow you to specify additional options when you insert the fitting.