Additional Parameters of Boolean Operation |

|

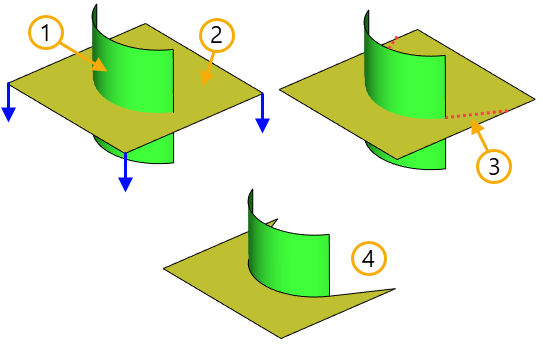

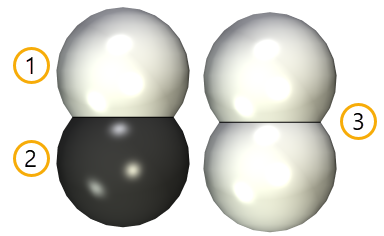

Extension of Edges

If one surface does not fully intersect the other one, the Boolean won't work. To fix the situation, an option is provided among the Boolean operation parameters for extending edges of the target or the tool up to the next edge or the body boundary. In this case, the intersection line between these two bodies will be extended tangentially up to the selected edge or to the boundary of one of the operands.

1. Target body

2. Tool body

3. Intersection line extended tangentially on the tool body

4 Result of Boolean Addition between surface bodies, the options Operands Treatment > Target, Tool > By Normal and Extension of Edges > Target Bodies > To Nearest Edge are enabled

Operands Treatment

The Boolean operation can perceive the faces of surface bodies as faces of a solid body, conditionally adding volume to them in the selected direction. The operand interpretation option allows you to choose how the surface will be perceived by the command and in which direction the volume will be completed on the surface faces.

There are three options for interpreting a surface body:

•as a surface body

•behind direction of normal

•by direction of normal

Depending on how it is interpreted by the system, different results of the Boolean operation will be generated. You can define surface bodies by selecting the appropriate values in the drop-down lists of operand treatment.

Results of the Boolean operations depending on the interpretation of operands are described in Boolean Addition, Boolean Subtraction, Boolean Intersection sections.

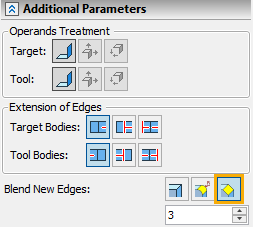

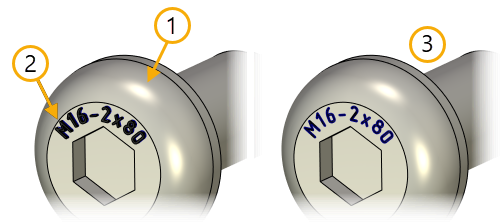

Blend New Edges

Another capability of Boolean operations is blending new edges. By new edges, we mean the edges created as a result of intersecting faces of the operands. As the operands' geometry changes, the system will automatically track the increasing or decreasing number of new edges and create blending. You can select the type of blending in the command: round or chamfer, and specify the blending radius.

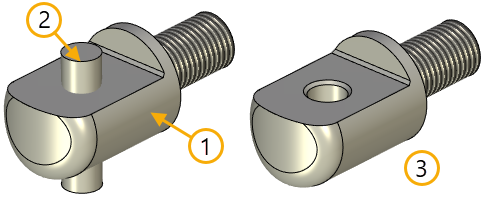

1. Target body

2. Tool body

3. Result of Boolean operation Subtraction with creation of chamfer on new edges

Use Pattern Copying

If a 3D array is used as one of the operands, you can significantly reduce the time of executing the Boolean operation by turning on the parameter Use Pattern Copying.

Allow Missing Operand

By turning on the Allow Missing Operand parameter in the Boolean being created, you will be able to suppress one of the operands in the future, and still keep the result of the Boolean operation.

Create Body

If as a result of creating a Boolean operation both a solid and a surface body can be formed, then the required type can be selected using the Create Body option in the additional operation parameters. If set to Default, the command will create the priority type of the resulting body.

Source bodies |

Boolean "Subtraction" operation result |

|

|

1. Target body with treatment behind normal 2. Tool body with treatment by normal 3. Result is selected - Body |

|

As noted earlier, this option is advisory in nature. If it is impossible to form the selected type of the resulting body, the value of this parameter will be ignored.

Material of newly created faces

To determine the material to which the result of the Boolean operation is applied, the combination of parameters is used. In addition to material parameters found on the General tab and common for all operations (the Source, Main, Covering parameters), the material assignment parameter for the new faces, which are created as a result of applying Boolean operation, is also taken into account.

This parameter can take one of the three values:

•Material of target body. In this case the main material or the material of the covering (if it is specified) will be assigned for the new faces according to the parameters of the first operand. If there are several first operands and they are with different materials, then on the new faces the material of that operand which participated in formation of these faces will be saved;

1. Target body

2. Tool body

3. Result of Boolean operation Addition

•Material of tool body. With this value, the material of the faces of the tool body, which participated in the formation of new faces, will be transferred to these new faces. This can be the main material, the cover material if specified, and even the material of the material setting operation. For example, as a result of the Boolean operation Subtraction between the target body with the material steel and the tool body with the material black plastic, black plastic material will be imposed on the created faces of the resulting body. If there are several tool bodies and they have different materials, then the material of the operand that participated in the formation of these faces will be stored on the new faces.

1. Target body - steel

2. Tool body - black plastic

3. Result of Boolean operation Subtraction

•Main material of target body. The action of this parameter is analogous to the first parameter Material of target body, except the case when the material of the covering is specified. In this case the material of the covering is not used on the new faces. For example, if in a part with the main material Steel and with covering Copper we create a hole with the help of the Boolean operation, the hole inside will appear as steel in accordance with the main material.