Processing of Junctures of Face Taper |

|

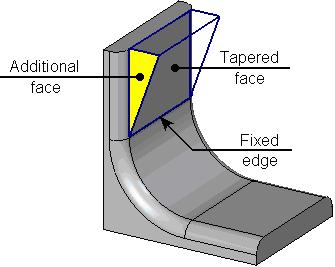

Processing of Junctures between Tapered and Adjacent to Them Faces

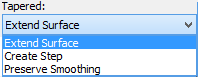

When creating a taper, there is a possibility of creating a gap between the tapered and adjacent to them non-tapered faces. To process these gaps, it is possible to use two methods:

•Creating auxiliary flat faces;

•Extending the surface of the non-tapered face.

The first way implies creation of an additional flat face for patching the gap at the connection. The second way allows preserving transition between those faces. In this way, a portion of the tapered face will be trimmed by the surface created by extending the adjacent face.

In some cases, creation of the additional face is the only possible way of closing the gap at the faces connection. This exact case is shown on the right-hand diagram.

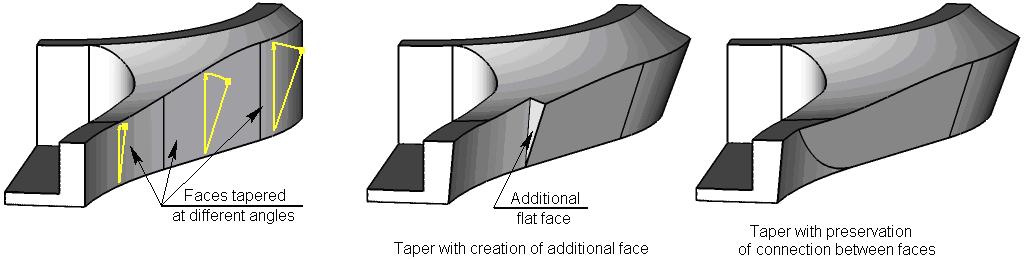

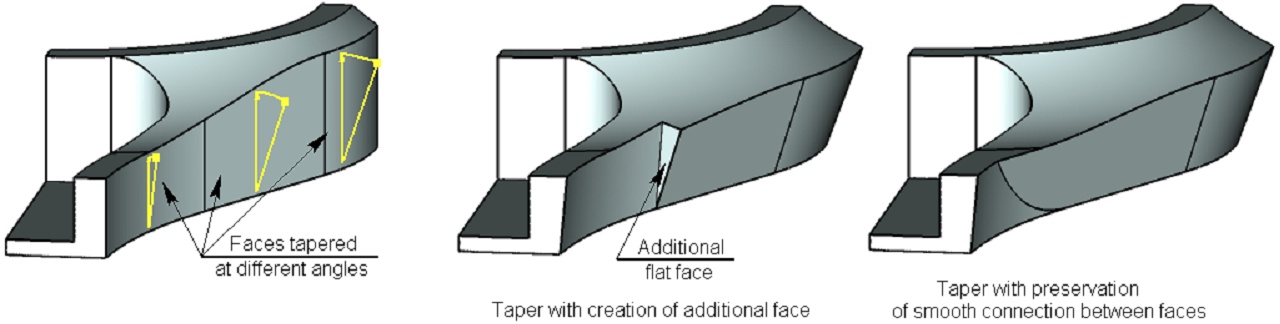

Processing of Junctures between Tapered Faces

When the adjacent faces are tapered at different angles, a gap can be created between them. For correcting this situation, it is possible to use the following methods:

•Creating additional flat faces;

•Extending the surface of non-tapered face;

•Preserving smooth connection.

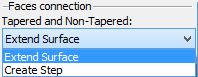

Processing connection between faces

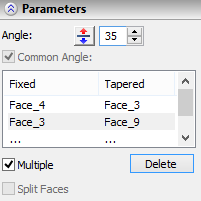

You can select a method for connecting the tapered face and its adjacent faces, using the parameter “Faces Connection/Tapered and Non-tapered” in the parameters window.

Similarly, you can select a method for connecting the tapered faces.

Processing faces together

For combined processing of two adjacent faces, it is required to select one of them as a fixed face for another, and turn on the flag Multiple in the command’s parameters window.

In the same way, it is possible to create a taper for three and more faces.