Document Parameters > Document > 3D |

|

This tab collects general parameters related to 3D modeling:

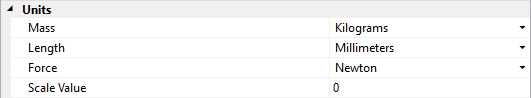

Units

Units section. Defines measurement units of the elements and operations on the 3D scene.

•Mass. Defines mass units for solid objects of 3D scene.

•Length. Defines length units for 3D objects.

•Force. Defines force units for 3D objects. Used in Measure command and loads definition in Analysis studies.

Scale Value. Parameter is used when the value of Length parameter is set to User. Value of this field defines ratio of user-defined custom length unit of measurement to a one meter. Accepted range of values - from 0 to 100. E.g.:

•Scale Value = 1

Custom length unit is equal to one meter.

•Scale Value = 100

Custom length unit is equal to one centimeter.

•Scale Value = 0.1

Custom length unit is equal to ten meters.

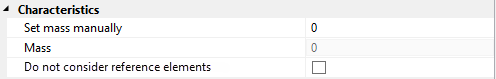

This tab controls the value of the $Weight hidden variable. This variable is used as a source of data about product weight, when filling product compositions and title blocks in the current document, and fragment weight, when the current document is inserted into an assembly as a fragment. By default the weight is calculated automatically as the total weight of all bodies existing in the document, and the weight of each body is calculated from the volume of the body and the density of its main material.

Set mass manually

This box allows to switch between calculating the weight automatically and specifying it manually:

•-1<Set mass manually<1

Value in this box rounded to a zero upon clicking OK. Product weight is calculated automatically.

•Set mass manually<-1 or >1

Value is saved upon clicking OK. Product weight is specified manually in the Mass box below.

Value in the Set mass manually box can be defined numerically or via a variable.

Mass

If product weight is specified manually, you should type its value into this box. Units of measurement are set above.

Do not consider reference elements

If this checkbox is enabled, then weight of reference elements is not taken into account, when calculating product weight automatically.

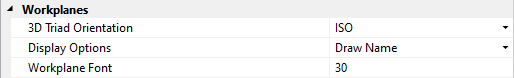

The Workplanes group defines the mode of displaying the workplane names and types. These parameters are displayed in the upper-left corner of the respective workplanes.

3D Triad Orientation

Defines the orientation of standard workplanes in relation to the global coordinate system (GCS). The orientation of these planes affects standard view points and corresponding standard 2D projections. Following orientation options are available:

•ISO

Normal directions of the Front, Left and Top workplanes coincide with directions of the Y, X and Z axes of the GCS correspondingly. Normal directions of the Right and Back workplanes are opposite to directions of the X and Y axes of the GCS correspondingly. Directions of the X and Y axes of the local coordinate system of the Top workplane do not coincide with directions of eponymous axes of the GCS.

•ANSI

Normal directions of the Back, Right and Top workplanes coincide with directions of the Y, X and Z axes of the GCS correspondingly. Normal directions of the Left and Front workplanes are opposite to directions of the X and Y axes of the GCS correspondingly. Directions of the X and Y axes of the local coordinate system of the Top workplane coincide with directions of eponymous axes of the GCS.

Display Options

Allows you to display/hide workplane types and names in 3D scene:

•Don’t display. Workplane name and type are not displayed.

•Draw Name. Sets the mode of displaying the workplane name according to the workplane type. Note that changing the workplane type does not affect the name. The name can be changed manually under the workplane parameters.

•Draw Type. Sets the mode of displaying the workplane type (Front, Left, etc.).

•Draw name and type. Both workplane name and type are displayed.

Workplane font

Defines font size for workplane names.

Image Quality. This parameter allows us to specify the degree of refinement of the model mesh consisting of planar triangular faces upon displaying the image in the 3D window. Higher quality of the image of the model increases the number of planar faces which slows down the work for large models or for insufficiently powerful video cards. If possible, it is recommended to minimize the quality of the image of the model.

If you're interested in how many triangles are used for displaying a specific model with specific mesh quality parameters, enable the Display graphics performance data checkbox in the Graphics Settings tab of the System Options dialog.

Edge Tolerance – the maximum distance between the curves of the model and edges of the mesh which approximate these curves;

Face Tolerance – the maximum distance between the surfaces of the model and planar faces of the mesh which approximate these surfaces;

Angle Tolerance – the maximum angle, specified in degrees, between the curves of the model and the edges of the mesh which approximate these curves. The angle is equal to the sum of angles between the edges of the mesh and the tangents to the original curve at the end points of the edges. This parameter also defines the maximally admissible angle between the surfaces of the model and the planar faces of the mesh which approximate these surfaces (i.e., the angle between the normals to the surface or face).

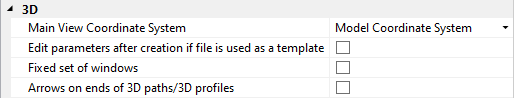

Main View Coordinate System. This parameter allows to specify a coordinate system defining the orientation of standard view points and corresponding standard 2D projections. The drop-down list contains all local coordinate systems existing in the current document and the Model Coordinate System (global coordinate system). The global coordinate system is used by default, so view directions of standard view points are opposite to normals of standard workplanes. However, selecting a different main view coordinate system doesn't affect standard workplanes, as they're always defined by the global coordinate system. Standard view points and 2D projections are available, regardless of the presence of eponymous workplanes in 3D model.

Changing main view coordinate system can be helpful, when working with imported geometry, parts created in context of assembly or in other cases, where model is oriented discordantly to desired view directions.

Local coordinate system selected as the main view coordinate system cannot be deleted.

Edit parameters after creation if file is used as template. The given parameter is also used only for the document which will become a prototype. Moreover, the document-prototype must have a set of external variables. Then, if the flag is enabled, upon creation of a new document on the basis of this prototype will immediately appear the window of the editor of external variables of the document being created.

Fixed set of windows. When the given parameter is set up, the current set of views (i.e., 2D and 3D windows) is getting fixed in the document. Upon subsequent openings of the document, modification of this set of views will not be possible. It will not be possible to delete one of the windows by reducing its size to zero (when moving the window's separator), or add a new view (the button of creation of a new view will not be available). This functionality is convenient for creation of templates with a set of views defined in advance.

Arrow ends of 3D paths/3D profiles.

|

|

Checkbox is disabled (default) |

Checkbox is enabled |

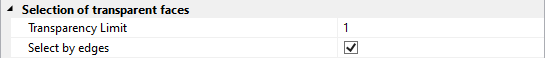

Selection of Transparent Faces

The Selection of Transparent Faces group of parameters allows us to control selection of transparent faces in the 3D scene:

Transparency limit. This parameter can take values ranging from 0 to 1. It is possible to specify the transparency limit with the help of a variable. If transparency of some face of a body is higher than the indicated transparency limit, this face will be ignored when it is selected in the 3D scene.

Recall that transparency 0 corresponds to the absolutely opaque body (face), 1 – absolutely transparent. Transparency which is larger than 1 is impossible, therefore the value of the limit equal to 1 (default value) corresponds to the standard behavior of the system.

Select by Edges. If this flag is enabled, those faces whose transparency is larger than the specified limit can be selected by their edges (as in the wireframe mode). When the flag is disabled, such faces cannot be selected.

Mates

Mates group of parameters define performance of mates solver only for regenerating a 3D model.

Time (0-1). Defines the time limit of mates solver calculations. The limit is set as factor between 0 and 1 corresponding to “less” and “more” respectively.

Calculation method. Sets one of two available methods of calculation – precise or fast.

More information about calculation methods can be found in Mates chapter.

Precision. Specifies precision of mates calculations when regenerating a model. The parameter value can be specified from 0.000001 (10-6) to +∞. The precision value specifies the minimum value of mates deviation. If mates deviation exceeds the specified value, all mates will be recalculated. If there are no mates, which deviation exceeds the specified value, the recalculation will not be performed. This reduces model recalculation time.

Method of contacts definition - method of contact definition for bodies, which are not primitives. It is used in T-FLEX Dynamics, when contact analysis is included and in the command of movement of mated bodies. Following methods are available:

•Meshes

•Parasolid

Moreover, the 3D tab contains following sub-tabs:

•Annotations

oFont

Font, Dimensions, Alternative Dimensions, Symbols, Detailing Elements tabs in the Document group contain similar parameters as eponymous tabs in the Page group. In this case, parameters from the Document group are applied to elements in the 3D scene, while parameters from the Page group are applied to elements on the drawing.

•View

Page and Document groups contain eponymous View tabs. These tabs contain different parameters which are applicable to 2D and 3D windows accordingly.