Create 3D Weld > By Path |

|

To create a 3D weld by path, you need to perform following actions, upon calling the ![]() 3D Weld command:

3D Weld command:

3.Select source elements and define geometrical parameters of weld;

4.Define length of weld (optional step);

5.Define basic parameters and side processing (optional step);

6.Confirm the weld creation (![]() or <Ctrl>+<Enter>).

or <Ctrl>+<Enter>).

When creating a weld, you may also use dynamic preview and preview of operation result.

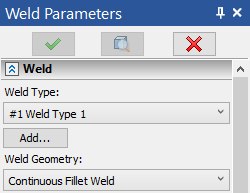

The type of weld can be selected in the Weld Type drop-down list located at the top of the Weld section of the command's parameters window. The list contains all types of welds created in the current T-FLEX CAD document.

If the required weld type is not yet created, you can use the button Add. Clicking this button starts the command of the new weld type creation. When the type is created, the system returns to the weld creation command. The created weld type will be automatically selected.

How to create a new weld type is described in the Weld Type section.

In addition to the user-created weld types, the list also contains the Non-Standard option, which allows creation of a weld not belonging to any type.

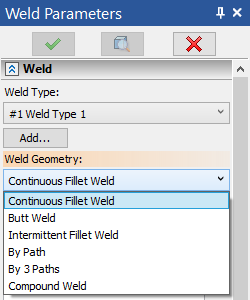

Select a geometry type using the Weld Geometry drop-down list located in the upper part of the Weld section of the command's parameters window.

Following geometry types are available:

•Butt

The Compound Weld option is not available in the list, if the Weld Type field specifies Non-Standard.

Source Elements and Geometrical Parameters

Upon selecting the By path option in the Weld Geometry drop-down list, the following automenu option for selecting the guide gets activated automatically:

|

<T> |

Select 1st Guide |

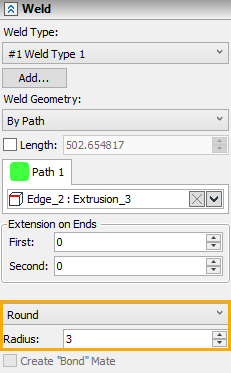

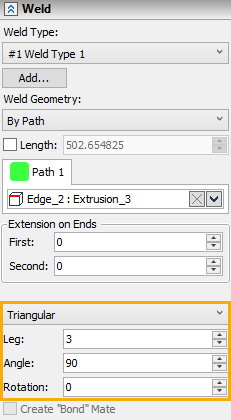

3D profiles, faces (in case of selecting a face, its contour is used as guide), edges, loops and 3D paths can be used as guides. Selected elements are put into the list Path 1 in the command’s parameters window. To cancel selection of a 3D object, select it in the list with the help of ![]() and press the button

and press the button ![]() .

.

If you want to clear the selection entirely, press the button ![]() in the parameters window or use the following option of the automenu:

in the parameters window or use the following option of the automenu:

|

<D> |

Cancel Selection of 1st Guide |

If the selected guide is not long enough, it is possible to increase the weld’s length by specifying the magnitude of the extensions. This can be done with the help of parameters of the group Extensions on End found in the command’s parameters window.

Parameters’ group found in the lower part of the Weld section of the parameters window allows the user to select the type of the weld’s profile: Round (circle) or Triangular. When selecting the circular profile it is necessary to indicate its Radius. For triangular profile you need to specify the length of the lateral side of the triangle (parameter Leg), angle between the sides of the triangle (parameter Angle) and the angle of rotation with respect to the direction of the profile orientation (parameter Rotation).

The direction of the triangular profile orientation can be specified with the help of the following option of the automenu:

|

<R> |

Select guide for defining profile orientation |

To clear the direction selection, use the following option:

|

<U> |

Cancel selection of guide for defining profile orientation |

The method of calculating the weld length is determined by the state of the Length checkbox located below the list of weld geometry types. When the checkbox is disabled, the weld length is calculated by the system automatically. When the checkbox is enabled, the length value is defined by the user in the input box next to the flag.

Basic Parameters and Side Processing

When using a user-created weld type, the parameters window contains the Basic Parameters, Face Side Processing and Back Side Processing sections. the content of these sections is the same as described for 2D welds. When using the Non-Standard weld type option, these sections are not available.

Parameters set in Basic Parameters, Face Side Processing and Back Side Processing sections are used for creation of weld symbols.

See Also: